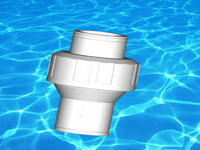

PVF-X00-CN Обратный клапан

Ginde PVC-U Fitting are the latest novel fittings developed by Ginde Plastic Pipe Industry Group and approved by the national authorities. The fittings are designed by our professional design staff with their appearance based on the reference of well-known foreign brands and in combination with Chinese cultural features. They are featured by simplicity, elegance, nature, utility and reliable performance and have passed the inspection conducted by the national inspection organizations. These fittings are processed by advanced injection molding process. All the materials are high-grade PVC or imported process modification auxiliary agent and prepared with green impact-resistant nano-materials through scientific formulation to make the fittings possess sufficient strength and other physical properties and greatly improve their comprehensive properties. All these fittings have passed the national authoritative inspection section. The design of fittings has ingeniously made use of material mechanics structural theory, so the design is reasonable, leading to appropriate adaptation between pipelines and fittings with compact structure. Special materials with damping effect have been added to provide properties such as sound and thermal insulation, shock and impact resistance. Besides, pipelines and fittings can be simply constructed, easily operated and their price is reasonable. They are widely used as pipelines for water supply and drainage in engineering and civil buildings (especially high-rise buildings) and in the conditions such as industrial protection, fluid pumping, agricultural low-porosity irrigation and drainage, cable conduit for communication.II. Production facilities and process flow

2.Production facilities

Our company has introduced the complete production facilities from world famous injection molding machine manufacturer Hong Kong Zhen Xiong Machinery. These production facilities are designed and manufactured with the most advanced automatization technologies, possessing advanced properties such as high-speed melting, automatic temperature control, high-speed injection molding, automatic feeding, PC software controlled whole-line process. Advanced production facilities are prerequisite to ensure high-quality products.

PC software system controlling the production process can be input in advance and preset according to technical regulations, start-up time, and temperature control standard. Meanwhile, all the modification of running speed, melt pressure, extrude output, torque load and regulations of equipment motor and screw rod is automatically monitored, recorded, stored for reading; it also can alarm dangerous conditions, automatically shut down and display suggestions or correcting。instructions on the screen. Therefore, it can guarantee fundamentally equipment in good condition as well as normal operation of production processes.

The advanced design and structure of machinery make use of the advanced injection molding process and special scientific compression ratio design, perfectly integrated with machinery structure. . It owns prominent performances such as repeated compression, moderate melting, and high-speed extruding production process. Meanwhile, it equipped with imported large-scale mixing equipment which owns the functions of automatic metering and convey, dust-free seal and uniform mixing and dispersing; therefore it can guarantee the continuous process of production automatization.

The advanced design and structure of machinery make use of the advanced injection molding process and special scientific compression ratio design, perfectly integrated with machinery structure. . It owns prominent performances such as repeated compression, moderate melting, and high-speed extruding production process. Meanwhile, it equipped with imported large-scale mixing equipment which owns the functions of automatic metering and convey, dust-free seal and uniform mixing and dispersing; therefore it can guarantee the continuous process of production automatization.

3. Quality control

Ginde Plastic Pipe Industry Group owns national level inspection and test center. Strict quality control has been implemented from material incoming inspection to production. Ginde company owns the advanced inspection equipment and professional inspection staff. The major inspection equipment are all introduced from famous manufacturers at home or abroad, such as Universal (tension) Tester, Vicat Softening Tester, Plastic Pipe Hydraulic Pressure Testing Machine, and Drop-Hammer Impact Tester. Therefore, experimental data can be ensured to be accurate and reliable, and the percent of pass of factory products is guaranteed

4. Major property indicators:

Physical and mechanical property indicators of PVC-U fittings for drainage:

Experimental Item Indicator

Vicat Softening Point 80°C

Oven Test Acceptance

Drop Impact Test No Cracking

Та бидэнтэй ХАНГАН НИЙЛҮҮЛЭЛТИЙН ГЭРЭЭ хийснээр үйлчилгээ авна уу.

Хямд үнийн баталгаа:

Бусад нийлүүлэгч дээр илүү хямд байвал, зөрүү төлбөрийг эргүүлэн олгоно.

Хүргэлтийн хураамж/Бүх төрлийн бараанд/

2,500,000₮ -с дээш бараа захиалгад хүргэлттэй. Барааны овор хэмжээнээс шалтгаалж хүргэлтийн төлбөрийг тооцно

Овор ихтэй бараа болон, орон нутагт тухайлсан тээврийн зардал нэмж тооцно.

Specifications for PVF-X00-CN Обратный клапан

| САНТЕХНИК Хувилбар | Φ40 or Φ50 or Φ63 or Φ32 |